Parameter

As more and more people pay attention to environmental protection, aluminum alloy profiles are used in many industries, such as solar bezel, LED lamp, LED bracket, LED housing. Aluminum alloy is light in weight compared with other metal materials, and the surface of the oxidized aluminum alloy is protected by a layer of anodizing film to resist corrosion. After anodizing, the surface of aluminum alloy is smooth, beautiful and easy to assemble with plastic light bar. The discarded aluminum alloy can be recovered and recycled, which reduces waste and gives the earth a lighter burden.

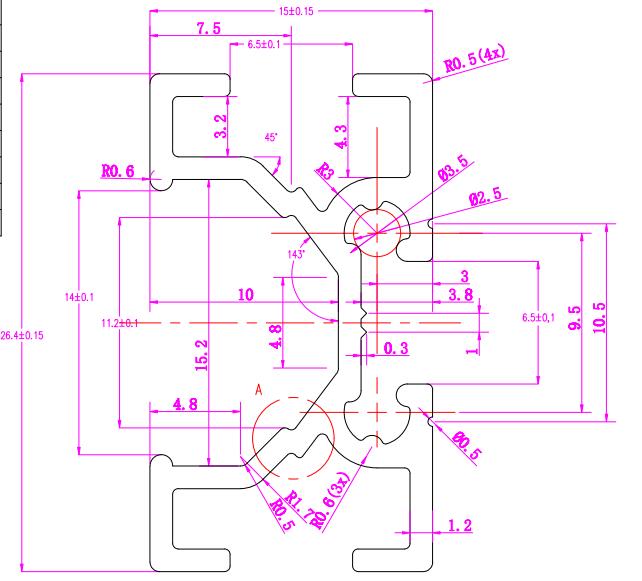

| Product name: | Aluminium Extrusion Profile for LED Lamp Holder LED Housing |

| Place of Origin: | Jiangsu, China |

| Material: | Aluminun Alloy |

| Alloy Temper: | 6063-T5 |

| Hardness: | 14 HW or custom |

| Shape: | Square with grooves |

| Surface Treatment: | Anodizing |

| anodizing film | 6-12 um, or custom |

| Al (Min): | 98.7% |

| Outer Diameter | 116 mm |

| Wall Thickness: | 0.9 mm |

| Length: | 1200mm, or custom |

| Color: | Silver |

| Application: | LED Lamp, LED Housing |

| Brand Name: | xing yong lv Ye |

| Certificate: | ISO 9001:2015,ISO/TS 16949:2016 |

| Quality Standard | GB/T6892-2008,GB/T5237-2008 |

After anodizing, the aluminum profile can be exposed to the air. The anodizing film on the aluminum profile surface can prevent corrosion and ensure that the aluminum alloy will not be oxidized and deformed in the air.

The worker only needs to align the slots, insert the plastic parts into the corresponding slots of the aluminum profile, and then gently press, and it is assembled. When disassembling the luminance, remove the screws and slide the aluminum profile in the direction of the slot and it will be disassembled.

The aluminum profile will be packaged by poly bag or EPE to protect the aluminum film, and then put into carton, or several pieces wrap to be a bundle, then packaged by Kraft paper. After that the aluminum profile can not be damage during the transportation.

Detail